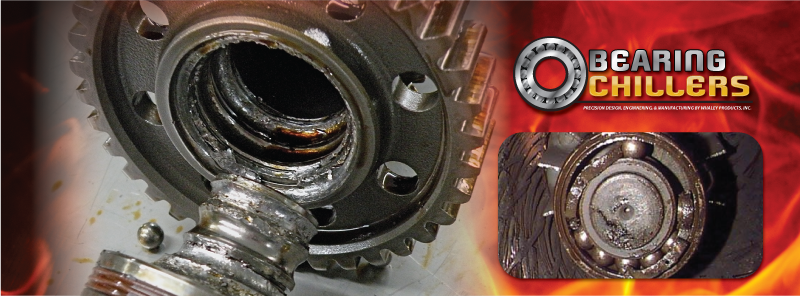

Bearing Problems and Fixing Them

Bearings solve many problems and have many advantages. Unfortunately, perfection doesn’t always happen. Depending on the industry and the use of the bearings, different variables can cause problems. Below are a variety of bearing problems and how fix them.

Foreign Matter– alien particles can cause wear and pitting

Common particulates- dirt, abrasive grit, lint, dust, steel chips

Fix: Clean with water, air, or mechanical removal

Improper Mounting- mounted on a press fit, of rotating ring

Mounting on shafts- causes denting

Loose shaft- produce heat, and foreign matter, cause wear

Loose Housing- similar to above

Excessive Tight Fits- cause rings to crack, creates high operating temperatures

Out of Round Housing- localized overloading, abnormal wear on surfaces,

Poor Finishing- break down of bearing seat

Fix: Review material, and check machine weekly

Bearing Misalignment- bent shafts, out of square shafts/spacers/clamping nuts

Overheating and separator failure

Fix: Inspect raceways, and ball tracks

Fluting- electrical damage

Currents pass through a bearing, cause arcing and burning

Early spalling and bearings need to be replaced

Small burns form on the rings

Fix: Inspect wires and parts of the machine, listen for problems as well

Corrosion, Fatigue, Improper Lubrication

Acids, water, and solvents can damage bearings, create excessive or abnormal wear

Excessive temperature reversals can occur

Flaking can occur, and surface deduction

Lubrication – overheating or excessive wear

Fix: Inspect parts regularly, apply lube, and keep dampness to a minimum

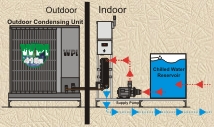

Whaley Products

Packaged Chillers Non-expandable (integrated pump tank) 1.5Ton – 20Ton Single / Dual Circuits Single / Dual Pumps |

SAE Series Modular Chillers Expandable (pump & tank on separate skid) 1.5Ton – 200Ton Single / Dual Circuits |

SAR Series Split Chillers Expandable (Outdoor Condensing Unit) (pump, tank, evaporator on indoor skid) 1.5Ton – 200Ton Single / Dual Circuits |